Below is the extensive range of crumb rubber ancillaries that we offer.

AIR SCRUBBER

removes offending odours from the exhaust air of dryer.

ACID TANK

stores formic acid and other liquid chemicals.

BELT CONVEYOR

transfers rubber between processing facilities.

BUCKET ELEVATOR

transfers rubber from wash blend tank to subsequent processing facility.

BULKING STIRRER

mixes and blends latex in the bulking tank.

COOLING CHAMBER

is used to cool down the rubber after the rubber is processed through the Dry Mode Prebreaker.

CYCLONE HOPPER

dewaters final size reduced rubber before it is placed into dryer trolleys.

FILLING STATION

consists of a vibrating screen and mobile hopper, used to dewater rubber before it is placed into dryer trolleys.

GRANULES TRANSFER PUMP

is used to transfer final size-reduced rubber to the filling station.

JETTING PUMP

jets, washes and blends rubber in the wash blend tank.

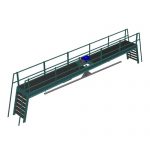

LUMP PUSHER BRIDGE

pushes rubber to opposite end of soaking tank.

MAINTENANCE GRINDER

is used for surfacing, grinding and sharpening knives and die plates.

MECHANICAL PADDLE

circulates rubber in wash blend tank and pushes rubber to Bucket Elevators / Screw Conveyors.

METAL DETECTOR

detects metal contaminants.

PNEUMATIC TRANSFER BLOWER

is used to transfer rubber without using water as a medium of transfer from the wet process to the dryer.

ROLLER BAGGING CONVEYOR

holds plastic bags for packing rubber bales.

ROTARY DRUM

removes contaminants at the early stages of processing.

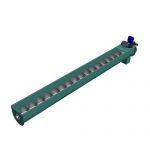

SCREW CONVEYOR

transfers rubber from wash blend tank to subsequent processing facility.

STIRRER

moves, agitates, washes and blends rubber in wash blend tank.

SUBMARINE SCREW CONVEYOR

removes floating dirt.