ABB Ability™ Condition Monitoring for Powertrain

FREQUENCY CONVERTER

Condition Monitors For Drivers

Operating parameters Errors, warnings, events E-mail notifications Drive Benchmarking

MOTOR

Smart Sensor For Motors

Vibrations (3D) Temperature surface Bearing condition indicator Power, speed, frequency Operating hours, starts Relubrication Note

BEARING

Smart Sensor For Bearings

Vibration Temperature surface Bearing condition indicators

PUMP

Smart Sensor For Pumps

Vibrations (3D) Temperature surface Pump speed Misalignment Loose seat Unbalance Operating hours

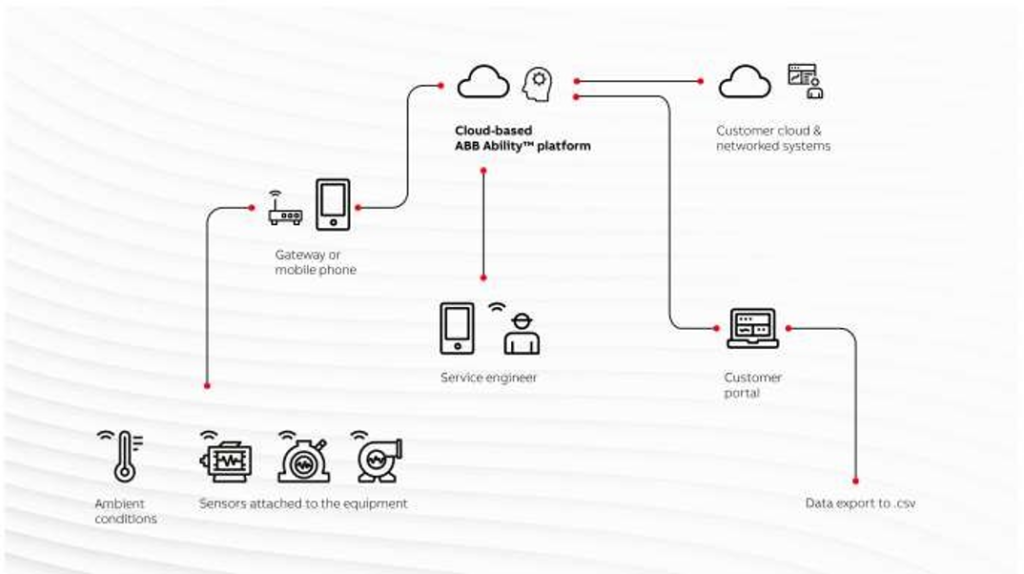

How The Communication Works ?

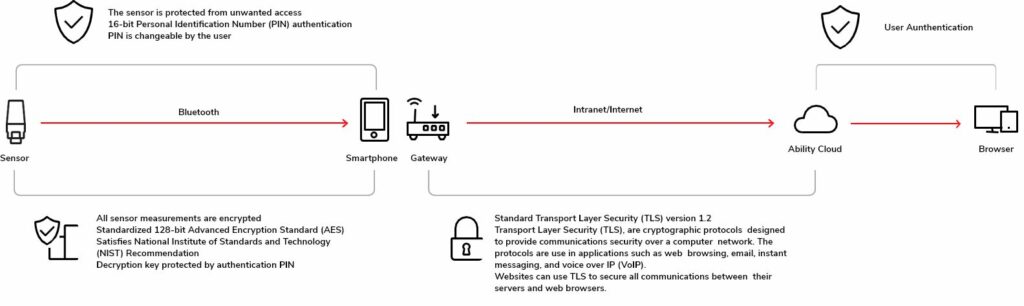

Communication Security Overview

Monitoring Mobile App and PC Web Portal

Mobile App

Easy Overview of Status at the time of measurement with traffic lights

PC Web Portal

Trends observable over selected monitoring period More insights with Condition Indices

Report Overview

Fleet Report

Asset Report

Installation Example

Voice Of The Customer

Global Agri Business reduces downtime with ABB Ability™ Smart Sensors

“What I like most about the sensor is its simplicity. It can be put on any type of motor and the data is transmitted using Bluetooth. The overhead cost is low, which makes it viable, even on a large scale,”

“The savings from preventing only one motor failure has already recovered their investment in equipping smart sensors on a number of motors at its factories.”

ABB Ability™ Condition Monitoring brings predictive maintenance to an Italian factory that never sleeps

“The smart sensors have already detected motor anomalies, signaling alarm states. For example, the sensors identified the exact moment when a water pump started to fail,”

Case Study

Site inspection revealed that the absorbent pad was stuck on the cooling fan cover affecting the air flow for cooling . Sensors helps in picking up condition at site, preventing winding failure when exposed to high temperature

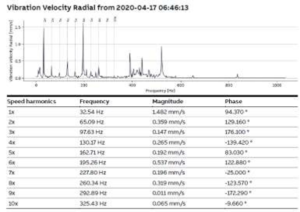

High vibration trended over a period of time, further investigation some sticky polymer stuck on the feed roller over certain running condition which causes such abnormality

Bearing condition exhibit abnormalities crossing Alarm levels in January. Site inspection observed bearing noise and regreasing was performed. Condition improves for a period of time, with slight increase of levels within alert range. The trend is closely monitored. In March, decision for bearing replacement is taken when condition crosses the alarm zone continuously. Bearing replacement is performed and condition improves upon start up.